The only thing standing between you and your goal is the bullshit story you keep telling yourself as to why you can't achieve it.

When it comes to your product or concept, we realise that it is crucially essential to have the correct bearing supplier who knows your particular needs and is able to help you identify, source and easily provides the best bearing for your application.

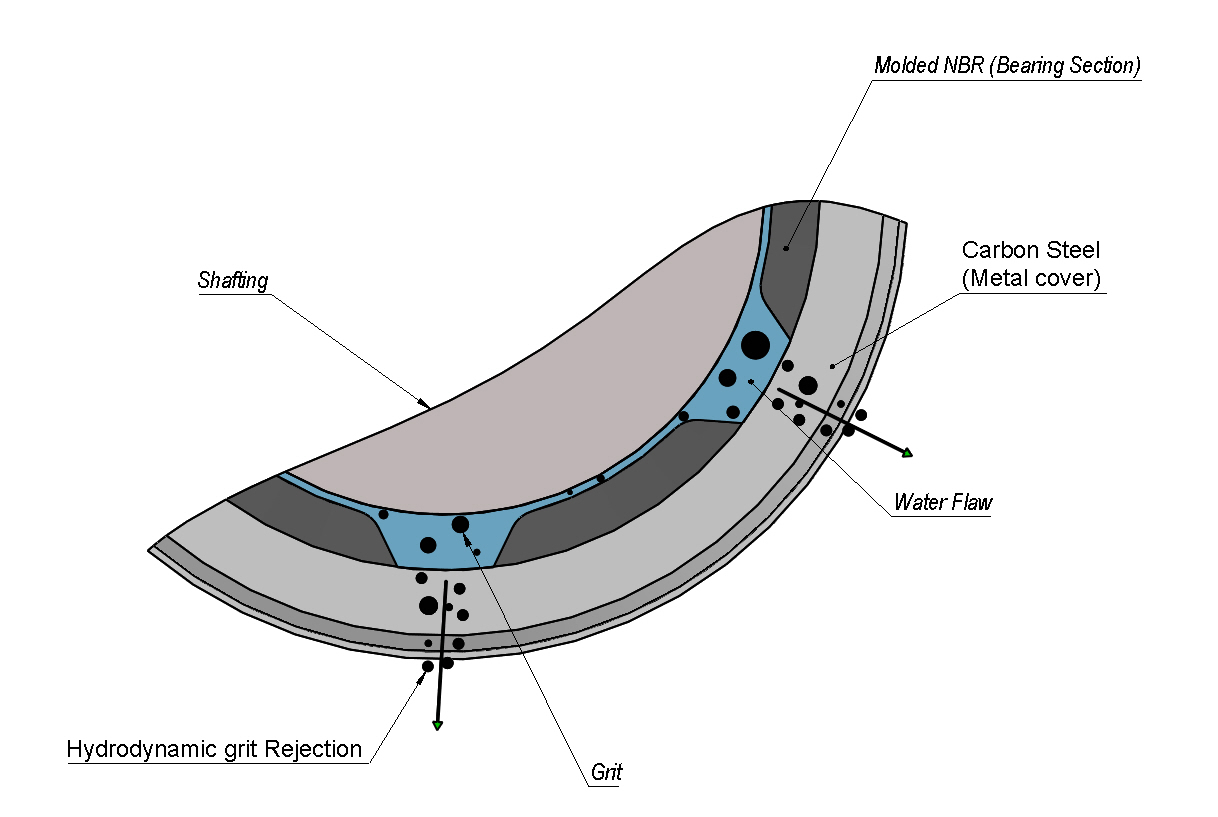

At Flextron, we will produce Cutlass Rubber Brass Bush Bearings made of bronze/brass/copper/stainless steel/alloy steel with rubber bonding, such as NBR, Neoprene, HNBR, XNBR & Polyurethane. We use our existing network of premium suppliers to satisfy the concept and product requirements while also remaining competitively priced relative to other bearing manufacturers in the global market.

At Flextron, we offer customizations in a number of ways, including the production of exterior shells from different materials such as carbon steel, stainless steel, bronze metal, plastic engineering such as PTFE, Nylon, ABS and so on. In addition, our products come with several features, such as:

Flextron is the largest exporter of CUTLASS BEARING BUSH in Italy, Spain, Turkey, Germany, France and Japan.

Ideally, it is impractical to continue to refurbish a bearing product for small bearings. Nevertheless, economic benefits could theoretically be made with wider bearings (6-inch bore and above). In specific, bearings like slewing circles, cylindrical roller bearings and spherical roller bearings are ideal for renovation.

Bearings play a crucial role and usually differ based on the application and industry. Hence, we highly recommend that you contact one of our bearing application engineers as you choose the design requirements. We provide professional sales and technical personnel to assist in the design and procurement process, optimise efficiency and ensure success.

Lubricating is the most essential element in determining the shelf life of the "properly stored" Cutlass Bearing Bush. Oils and grease have a shelf life (expiry dates). Otherwise, given that the bearing is correctly stored (usually in its initial factory packaging), the future consequences of corrosion and decay will be negligible and will not greatly impair the shelf life.